Precision Stampings

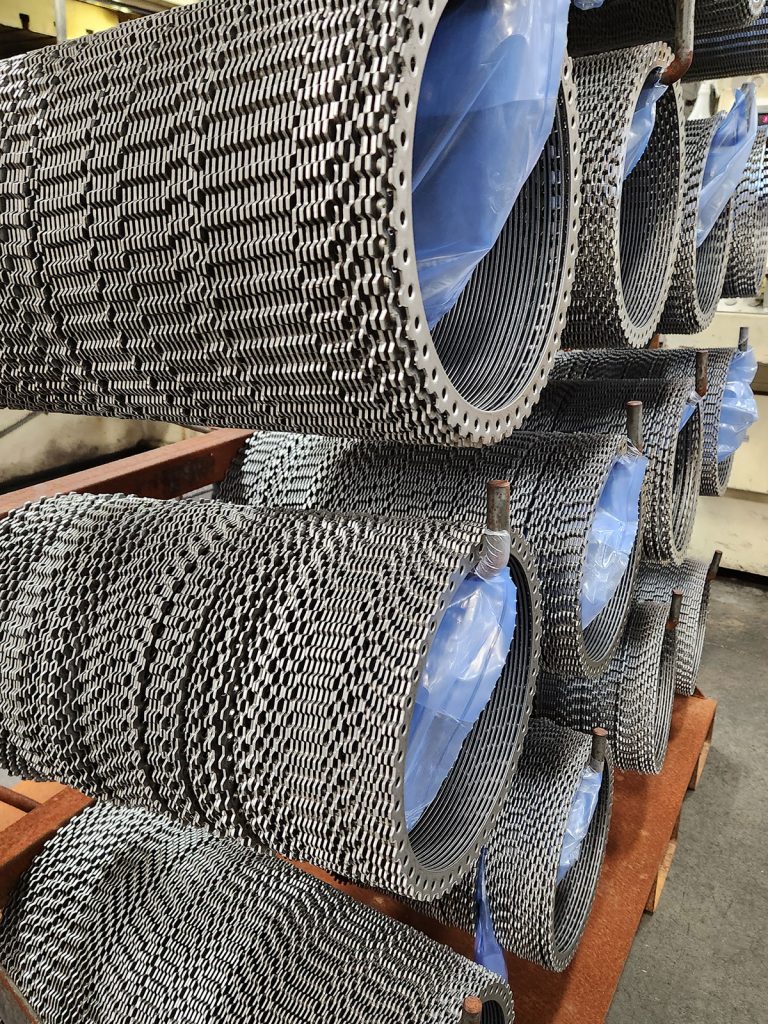

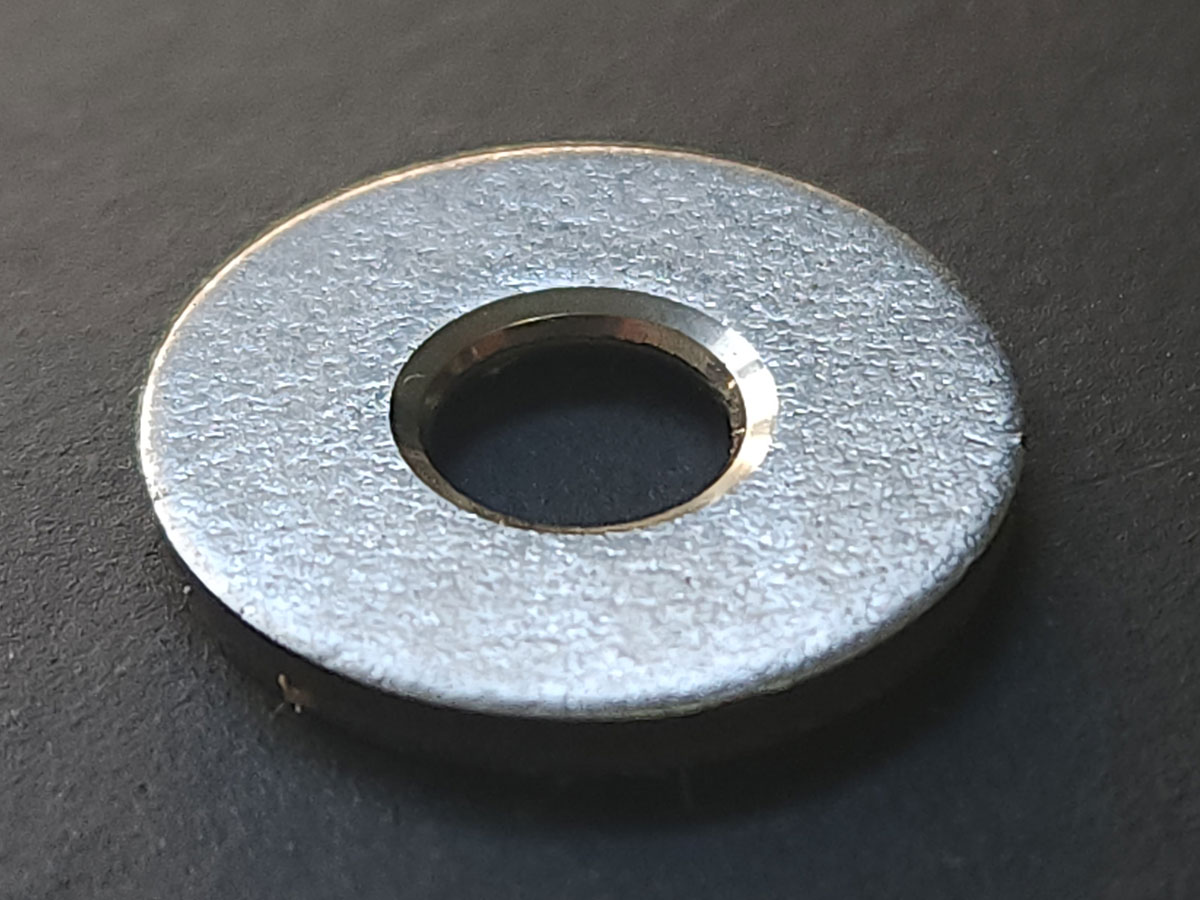

Many times, by converting a machined part into a stamping, you can eliminate a complete machining operation and realized over 50% savings in raw material. The savings are tremendous when working in costly materials such as copper and stainless. ART Metals Group has the coining equipment required to convert machined parts into stampings.

Many times, by converting a machined part into a stamping, you can eliminate a complete machining operation and realized over 50% savings in raw material. The savings are tremendous when working in costly materials such as copper and stainless. ART Metals Group has the coining equipment required to convert machined parts into stampings.

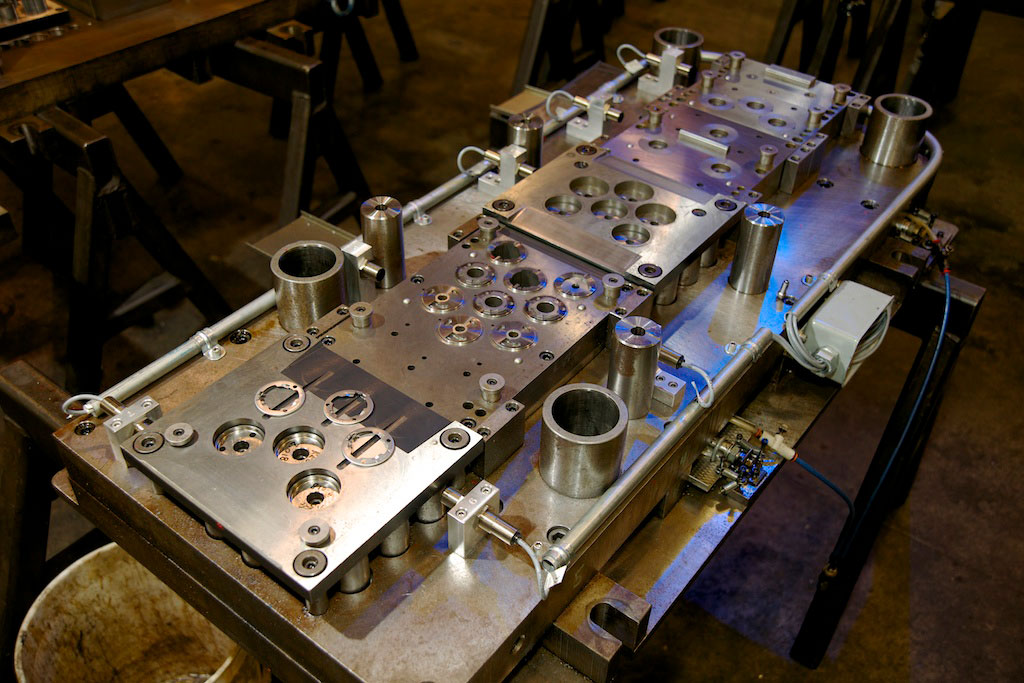

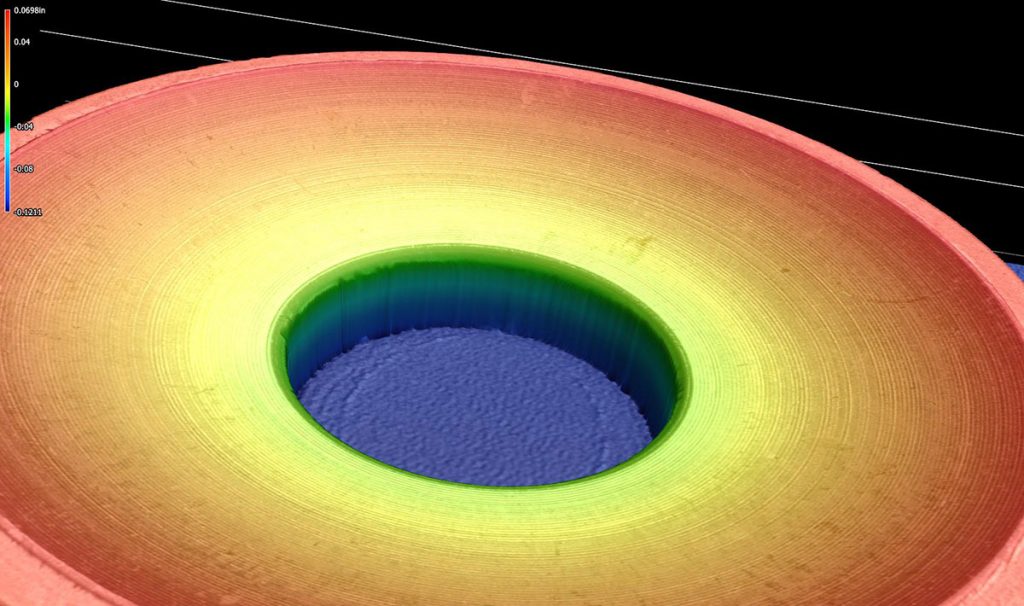

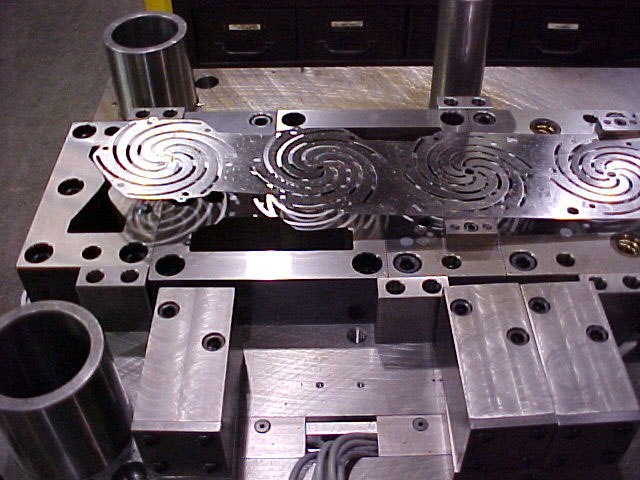

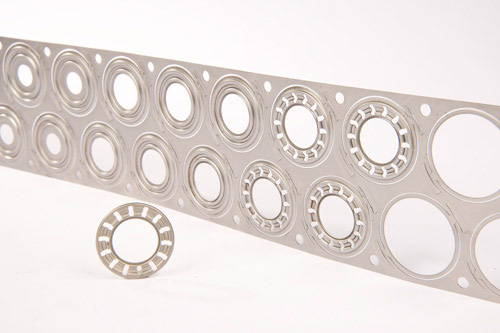

The Company has two 800 ton knuckle presses which are able to hold tight tolerances and coin minimum corner radii which were previously only achievable by machining. Whether using a compound blank die to hold concentricity ID to OD on bearing races, or progressive dies with intricate geometry, ART has the expertise to meet your needs. In forming stamped parts, angle dimensions also play a critical role in functionality. Our knuckle presses provide the dwell time needed for the metal to take a set and hold these dimensions.

Material Reduction

Instead of machining down from large ingots, challenge ART Metals Group to create your part from strip material and coin into finished shape. The material reduction alone is worth a phone call to see if ART Metals Group can convert your machining into a stamping, not to mention the cost savings by freeing up machine time and labor.

Challenge us with your requirements.