Coining & Embossing

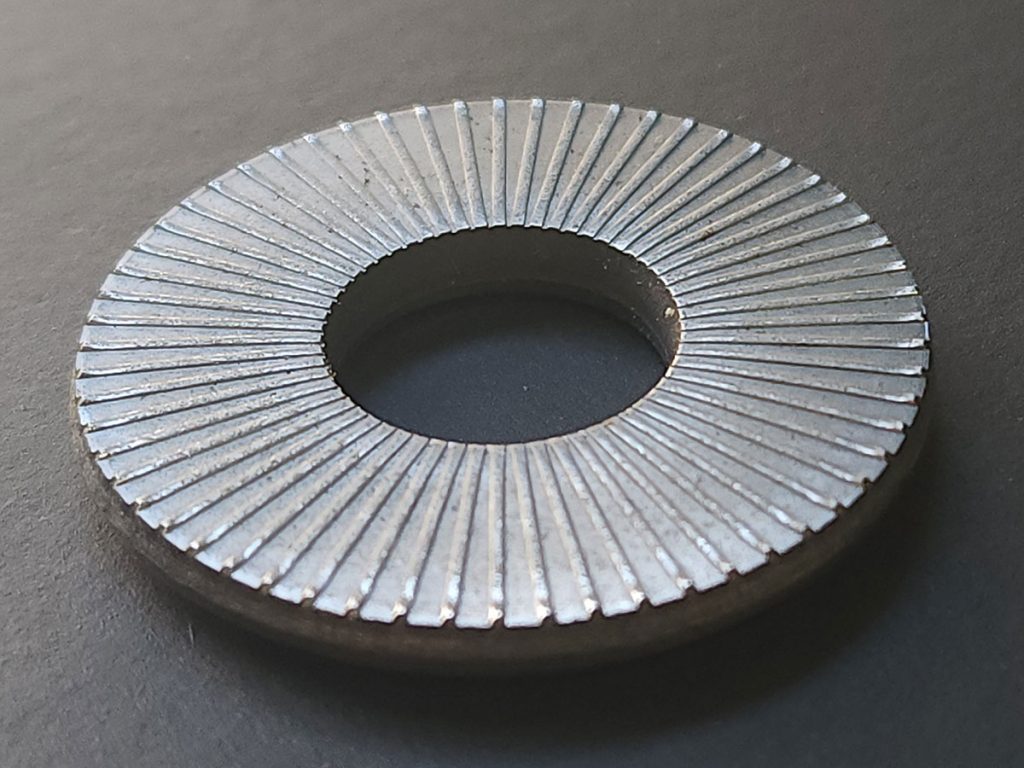

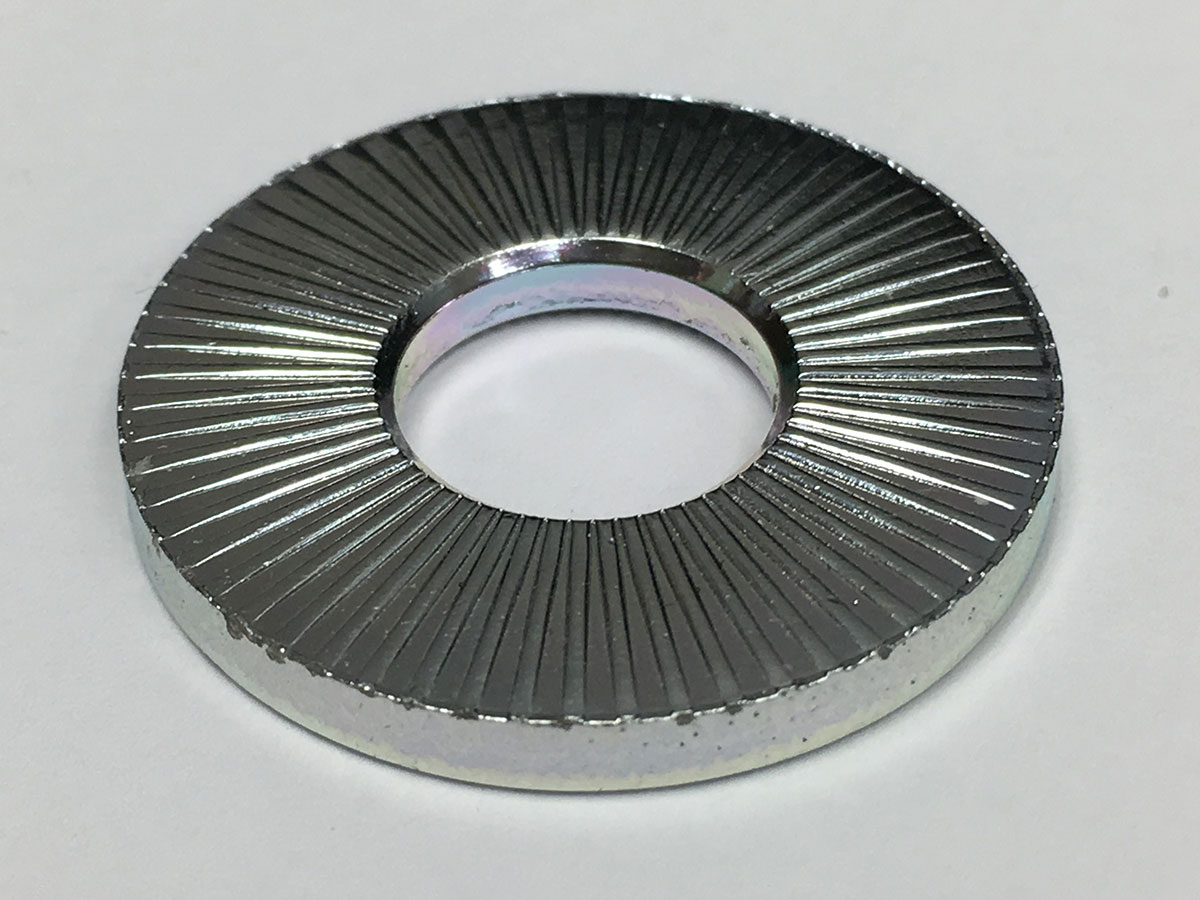

Coining and embossing are two core stamping competencies of ART Metals Group. These operations produce complex shapes held to very tight tolerances. Coining operations can eliminate or reduce subsequent machining and or grinding processes. We have several coining knuckle joint presses with capacities of up to 800 tons.

Coining and embossing are two core stamping competencies of ART Metals Group. These operations produce complex shapes held to very tight tolerances. Coining operations can eliminate or reduce subsequent machining and or grinding processes. We have several coining knuckle joint presses with capacities of up to 800 tons.

Progressive and Compound Die Coining Services

- Eliminate or reduce costly machining for near net shape products

- Improves existing designs for functionality and cost reduction

- Ideal for raised and lowered contours and features, countersinks, burr- free – smoother edges

- Can be used to produce edge finishes similar to fine blanking

- Mass produce complex parts economically and quickly

- On site tool and die makers and high-quality tool room

Our team’s experience and expertise is unmatched in providing stamping and coining solutions for customers. We can help in lowering the cost of your parts without sacrificing any product integrity. By incorporating coining in the stamping operations, we can produce precise tolerances eliminating standard stamping edge break.

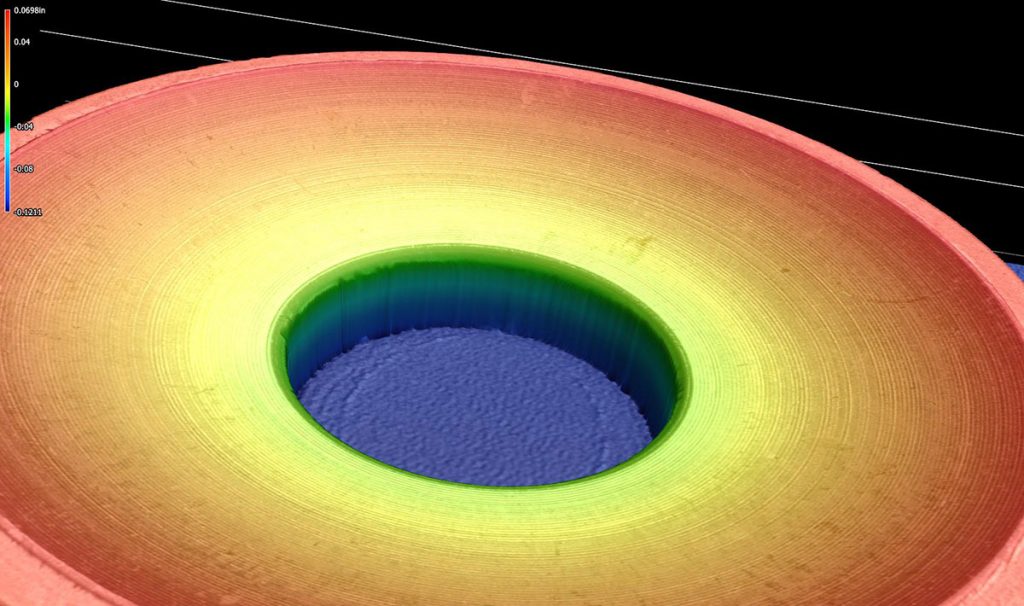

ART Metals Group achieves the coining of internal features to 75% edge bearing surface by using proper equipment and years of experience. There are several applications where an ID bearing wall is needed, this is where coining comes in. When quantities become too high for machine production, we can provide cost savings alternatives to machining. Contact us to discuss your project.