Automotive

ART Metals Group metal stamping provides essential components for a variety of applications in the automotive industry. We have extensive experience with automotive applications, having IATF 16949 and ISO 9000 certifications. We have been a participating supplier at one, two, and three tier levels.

ART Metals Group metal stamping provides essential components for a variety of applications in the automotive industry. We have extensive experience with automotive applications, having IATF 16949 and ISO 9000 certifications. We have been a participating supplier at one, two, and three tier levels.

Manufacturing Capabilities for the Automotive Market

Our team produces auto manufacturing components with extremely tight tolerances to meet precise manufacturing requirements. Our specialized stamping dies allow us to create automotive parts of various shapes, forms, and sizes. Our capabilities include stamping and forming of a wide range of metals, such as copper, stainless steel, carbon steel, and alloys.

ART Metals Group is able to engineer solutions for the manufacture of difficult and custom stampings, bearings, and assemblies. We house 16 presses ranging from 45 to 800 ton capacity. In addition, we have 9 assembly machines including a full service tool room.

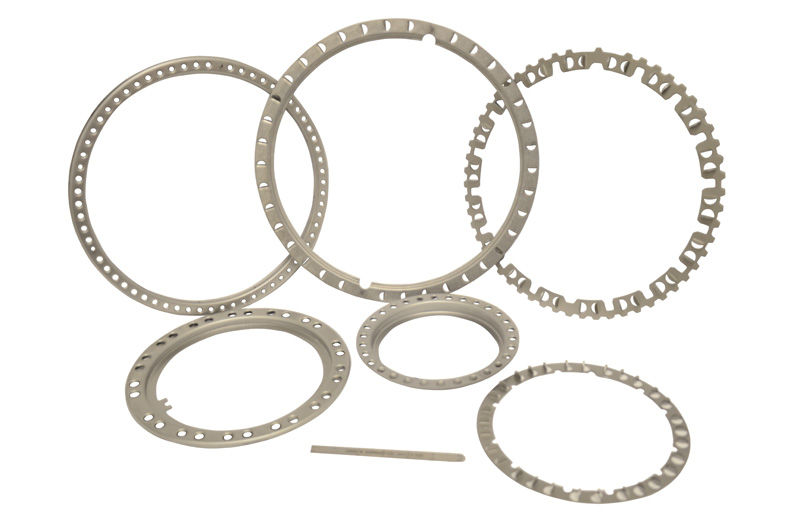

Automotive Assemblies and Components

ART Metals Group is a dependable contract manufacturer, supplying a wide variety of automotive metal stamped and formed products, and assemblies, such as:

- Washers – flat and conical washers

- Custom engineered washers – serrations, anti-rotation flag, chamfer

- Ball thrust bearing assemblies – for scissor jack applications

- Headlight clips – progressive die stainless steel

- Modern vehicle assemblies – bolts for interior components, drivetrain parts

- Progressive die stamping components – automotive transmission

- Spring pack assemblies – for truck transmissions

- Steel roller bearing assembly – automotive transmission