Progressive Die Stampings

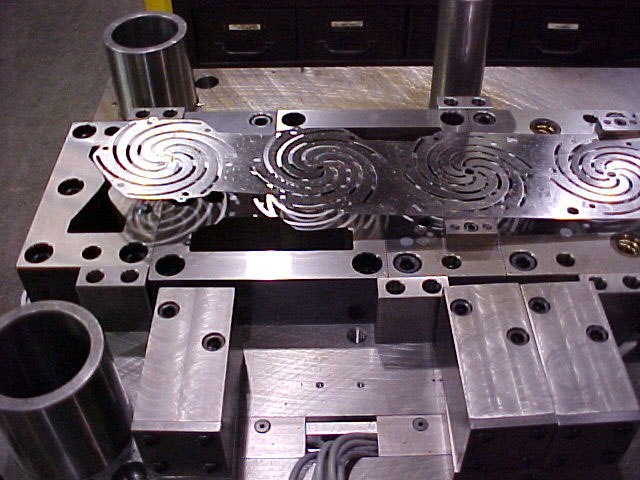

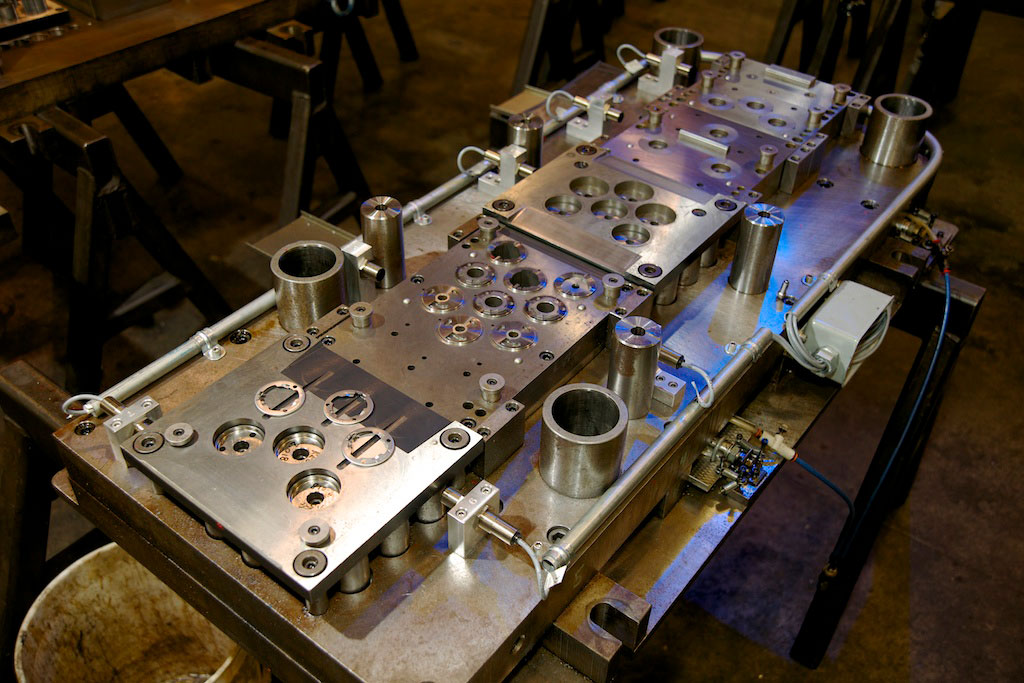

ART Metals Group runs stampings through progressive dies in any of our 45-800 ton presses. ART has incorporated compound blanking, coining, drawing, shaving, forming, as well as in-die tapping, inspection gauging, censoring and in-die insertion in our progressive dies.

ART Metals Group runs stampings through progressive dies in any of our 45-800 ton presses. ART has incorporated compound blanking, coining, drawing, shaving, forming, as well as in-die tapping, inspection gauging, censoring and in-die insertion in our progressive dies.

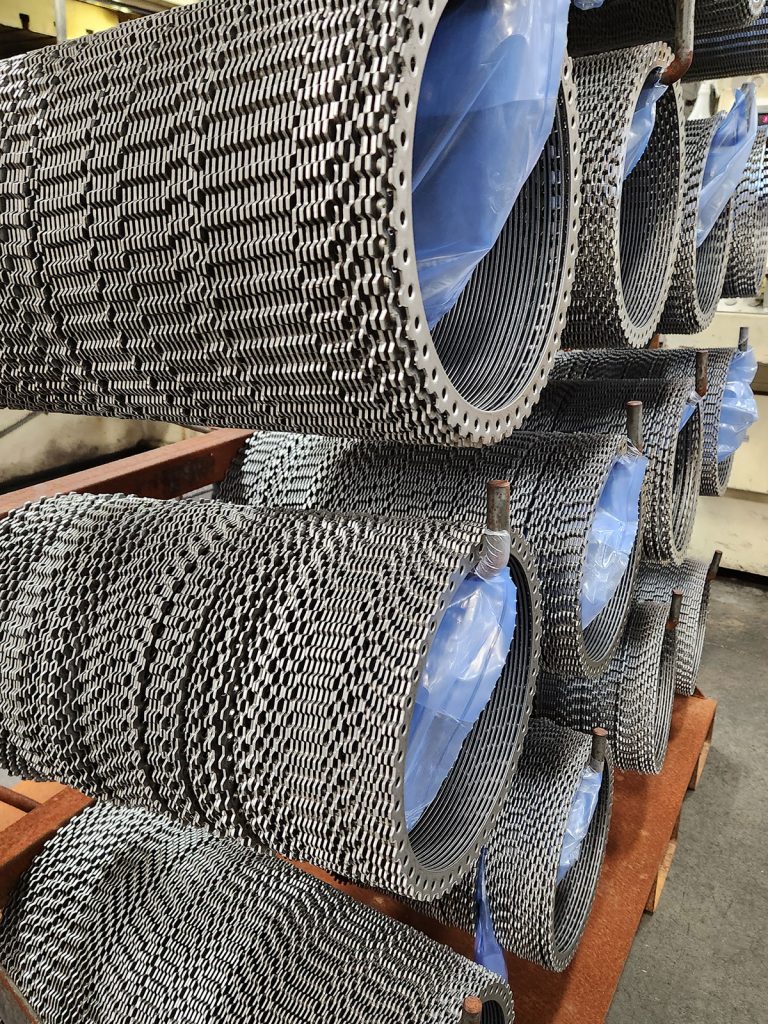

- High volume

- Coining

- Drawing

- Precision Stamping

- Light (.010″) to Heavy (.375″) Blanking

- In house die design and build

- Complex Shapes

- Diverse materials: stainless steel, aluminum, copper, annealed & pre-tempered carbon and stainless

Our tool room, dedicated solely to the support of manufacturing products for ART Metals Group. ART Metals Group can offer design, build and run for die builds/tooling. In addition, presses and stamping dies utilize the latest controls and sensor technologies in order to assure the best possible quality products for our customers.

Let us know how our progressive die expertise can help you.