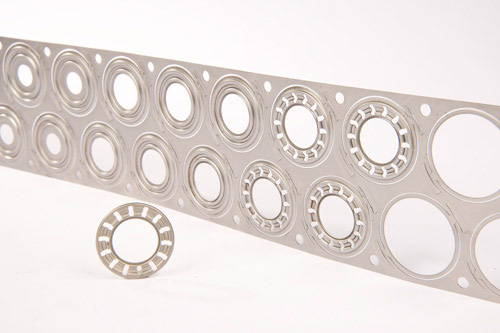

Steel Roller Bearing Assembly Components for the Automotive Industry

PROJECT DESCRIPTION

The roller bearing shown here was a joint effort with one of our long time customers. In order to win the bid to manufacture this bearing they needed it to be 30% lower in cost than the current product. In a collaborative effort our engineering staffs developed an innovative solution that utilized progressive die stamping and various processes to meet both cost and quality targets.

The assembly is composed of 1008, 1010, and 1074 steel, and consists of three thin gage parts, which are made to extremely tight tolerances. Progressive die stamping was performed on our 200 ton Minster straight side press, which was followed by heat treating and the application of black oxide plating per MIL-DTL-13924. At ART Metals we take quality seriously; everything that we manufacture is subject to stringent quality measures, and this project was no exception. Our customer’s satisfaction in our expertise and abilities translated in orders for 2.5 million of this component annually. To learn more about this project, or the processes used to manufacture it, see the table below or contact us directly.

Highlights of this Progressive Die Stamped Steel Bearing Project

These components are used for a bearing assembly in a car transmission.

Primary:

Co-Engineering/Design Improvements

Progressive Stamping

Secondary:

De-Burring

Black Oxide Plating

Heat Treating

Cleaning

200 Ton Minster Straight Side Press.

Outer Ring

- O.D.: Ø 1.450″

- Height: 0.091″ – 0.099″

Inner Thrust Washer

- O.D.: Ø 1.278″ – 1.282″

- Min I.D.: Ø 0.727″

- Max Height: 0.129

Retainer

- O.D.: Ø 1.359″ – 1.363″

- I.D.: Ø 0.787″ – 0.789″

Outer Ring: 1074 Steel

Inner Thrust Washer: 1074 Steel

Retainer: 1008 – 1010 Steel

Black Oxide Plated per MIL-DTL-13924

Head Treated

Control Plan, Dimensional Inspection

Automotive

4,500,000 per Year

4 weeks

Customer Specifications, 2D CAD Drawing

Roller Bearing Assembly Component